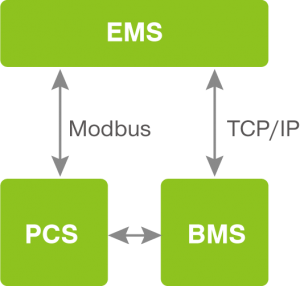

Industrial and commercial energy storage system consists of battery system (including BMS), EMS, PCS, air conditioning, fire protection system, monitoring and alarm system, etc., of which BMS and EMS, as the core control unit of the energy storage system, bear the important responsibility of battery management and energy management respectively, and their functions, performance and matching of software and hardware are directly related to the safety of the application of the energy storage system and the return on investment.

Battery Management System (BMS): taking charge of sensing in the system, it can monitor and control of battery storage systems to ensure their safety, stability and performance.

Energy Management System (EMS): responsible for decision-making in the system, it generally refers to the regulation and control integrated energy management system launched for lithium battery energy storage power stations, realizing real-time monitoring and diagnosis.

Power Conversion System (PCS):responsible for execution in the system, is a key part of the energy storage plant, controlling the charging and discharging of the batteries and performing the AC/DC conversion to supply power directly to the AC loads in the absence of the grid.

Battery Management System (BMS)

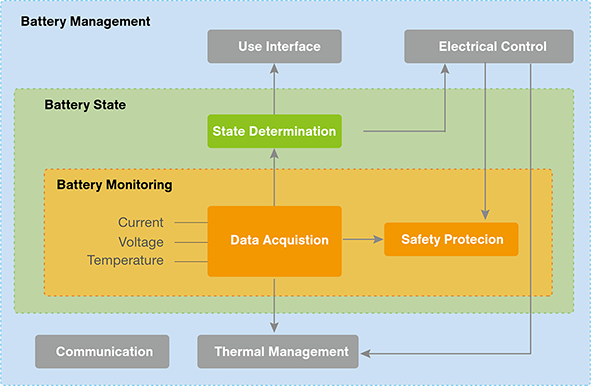

The full name of BMS is Battery Management System, which means the subsystem used to manage the battery energy storage system.

Function

BMS is mainly composed of monitoring module, control module, communication module and other parts. Its main function is to monitor and control the battery status in real time, including battery voltage, current, temperature, SOC and other parameters. Additionally, BMS can also protect and control the battery to ensure the safety and life of the battery.

In order to prevent the battery from overcharging and overdischarging, thus prolonging the service life of the battery and improving the efficiency of the battery’s use.

Not only that, the BMS also plays the role of data analysis, it needs to calculate and analyze the battery’s SOC (remaining battery capacity) and SOH (state of health of the battery), in order to observe the state of the battery, and once there is any abnormal information, it will be reported in a timely manner, so that the user will know that the battery has an abnormality in a timely manner.

Layered Awareness Architecture

In most BMS systems, there is a three-tier architecture .

1. Bottom layer: Slave BMU, the function of this level is mainly to realize the acquisition of battery cell voltage and temperature, and is responsible for the execution of battery equalization strategy. The information acquisition communicates with the second level via a communication link, usually using CAN or daisy chain communication..

2. Middle layer: Main control BCU, the main functions of this level are to realize the collection of cluster voltage, current and cluster insulation information, the control of contactors for battery pack protection, the collection of information from the first-stage BMU, and the estimation of battery state (SoX). The information is collected and communicated with the third stage via a communication link, usually using CAN or Ethernet..

3. Upper level: General control, for battery cluster management. The main function of this level is to collect the information transmitted by the second level BCU, store and display the information, etc., with real-time alarm function, with the control and contact feedback function of the main circuit breaker, and with the real-time communication function with PCS, EMS and local monitoring.

Technical requirements

Compared with the BMS for automotive power battery, energy storage BMS has a more complex structure.

First of all, the battery capacity, the level is different, BMS management of power supply level is higher, series and parallel connection required more batteries.

BMS has higher requirements for grid connection. There are higher requirements on the connection with the grid. The power battery is connected to the battery and the vehicle’s electronic system, so the technical requirements are lower.

Market

There are three main types of enterprises involved in the BMS market, namely vehicle manufacturers, power battery manufacturers, and independent BMS producers. Vehicle manufacturers and battery manufacturers carry out business in the form of independent research and development or cooperative development with BMS suppliers. Most of the domestic power battery leaders such as BYD, Ningde Times, Guoxuan Gaoke and AVIC Li-power battery manufacturers adopt the BMS+PACK mode of layout to provide battery packs and BMS packages. Independent BMS manufacturers currently have a large number of participants, and the BMS product line can be supplied to multiple industries.

At present, China’s BMS industry head enterprises have obvious advantages, specifically, in 2022, China’s new energy power battery BMS installed capacity of the top ten manufacturers share of 76.1%. Among them, the top three companies are BYD, Ningde Times and Tesla, all of which are vehicle manufacturers and battery manufacturers, with a share of 26.4%, 16.9% and 9% respectively. The share of independent BMS manufacturers is relatively low, and the largest independent BMS manufacturer in China, Li Xinneng, ranked fourth in terms of share, but the overall share is only 6.7%.

Moving from basic to advanced functions

1. Higher reliability

Since each battery unit has its own monitoring and control system, the reliability of distributed BMS is higher. Even if a single battery fails, other batteries can still work normally, and the overall performance of the system will not be greatly affected.

2. Easy to maintain and upgrade

Because the structure of distributed BMS is relatively simple, each battery cell can operate independently, so maintenance and upgrading is relatively easy. Once a battery unit fails, it can be replaced directly without having to shut down the whole system for maintenance and upgrading.

3. Stronger Flexibility

The monitoring and control system of distributed BMS is scattered in each battery unit, so the system is more flexible. Battery cells can be increased or decreased according to the actual demand, without having to consider the complexity of the system as a whole distributed.

Energy Management System (EMS)

EMS (Energy Management System), also known as energy management system, although the proportion of the whole energy storage system is not very large, but it is an extremely important core component of the whole energy storage system. It generally refers to the regulation and control of lithium battery storage power station launched an integrated energy management system.

Organization

Energy management system includes several parts, they will be shown as below.

1. Monitoring and collection: The energy management system monitors the generation, storage and consumption of energy in the energy storage facility in real time through sensors and instrumentation equipment. It is capable of collecting a variety of data, including battery charging and discharging status, temperature, voltage, current, and so on.

2. Data analysis and optimization: The energy management system relies on advanced data analysis technology to process and analyze the collected data in order to understand the working status and performance of the energy system. Through the analysis of data, it can identify potential problems in the energy system and provide optimization suggestions, such as adjusting charging and discharging strategies and optimizing energy utilization efficiency.

3. Energy scheduling and control: The energy management system can intelligently schedule and control energy based on real-time energy demand and system operation. It can reasonably arrange the charging and discharging operation of energy storage facilities according to demand forecast, electricity price situation, grid load and other factors, in order to realize the efficient utilization and saving of energy.

4. Fault detection and safety protection: The energy management system can timely detect and alarm fault conditions in the energy storage facility, such as battery over-discharge, over-charging, and temperature abnormality, in order to guarantee the safe operation of the energy storage facility. At the same time, it can also be linked with the distribution network system to realize remote control and protection of energy storage facilities.

Optimization of operation strategy and control strategy design is the key point

The design of optimized operation strategy and control strategy is the core point and difficulty of EMS products.

Considering energy storage charging and discharging characteristics, energy storage unit charging and discharging costs, and energy storage application benefits, and under the premise of meeting the grid dispatch control requirements, the design of optimized operation and control strategies can enhance the economic benefits of energy storage system operation and improve various technical indexes.

EMS products generally act as a bridge between the energy storage system and higher level information systems.

The energy storage system can join the grid scheduling, virtual power plant scheduling, “source-grid-load-storage” interaction, etc. through EMS.

EMS products and grid scheduling and other close coordination, and in the function has a certain similarity, the company needs to understand the operating characteristics of the grid, deep plowing grid-side information technology companies have knowledge know-how to accumulate, can form the ability to reuse, has a certain advantage.