As distributed photovoltaic (PV) systems gain widespread adoption, thanks to national and local government policies, ensuring waterproofing during installation has become a critical concern. Since these systems are still in the early market adoption stage, variations in design and construction quality can result in overlooked waterproofing, leading to leaks that may damage both the PV system and the building's structure. Here’s a closer look at how to ensure effective waterproofing during installation.

General Waterproofing Principles for Rooftops

The primary principle for waterproofing rooftops is "guide, don’t block," meaning water should be able to drain smoothly without pooling, even during heavy rainfall, ensuring the roof stays leak-free.

In cases where holes need to be drilled into the existing roof, the waterproofing approach should be tailored to the specific conditions. Let’s break down how to handle different roof types.

Concrete Flat Roof Waterproofing

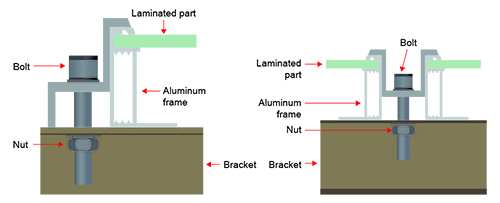

For newly constructed concrete flat roofs, the bolts should be embedded during the design phase, and waterproofing should follow standard methods. For existing buildings, when installing PV module bases, the waterproofing layer should extend over the base and metal fasteners, with sealing around anchor bolts. Waterproof sealant should be applied where penetrations occur, and an additional waterproof layer under the base is recommended. This extra layer ensures that even if there is a leak at the base, water won’t reach the structural layer.

Use of Chemical Anchors

For existing concrete flat roofs, if chemical anchors are used to secure the framework, the thickness of the protective or surface layer should be confirmed first. In the case of precast slab roofs with heavy load-bearing requirements, an additional concrete layer can be poured. Once cured, the framework can be fixed using chemical anchors.

For sloped roofs with tiles, it is essential to check the depth of the drilled holes. After fixing the chemical anchors, the point where the anchor penetrates the tiles should be sealed with waterproof sealant. Chemical anchors offer advantages such as high load-bearing capacity, fatigue resistance, and aging resistance, without exerting expansion force on the substrate. This means they won’t negatively impact the roof’s waterproofing.

Metal Roof Waterproofing

In metal roofs, the steel structure of the PV system must penetrate the original waterproof layer and the profiled steel plate, securing it to the building's main steel structure. Following standard metal roof waterproofing practices, vapor barriers, insulation, and waterproofing treatments are applied. Key steps include removing rust, sealing, and applying waterproof coatings to the base and surrounding areas.

For local leaks in metal roofs, high-quality neutral weather-resistant sealant should be used for sealing. If parts of the color steel plate are severely corroded, these sections should be replaced before installing the PV modules.

Conclusion

When installing PV systems, it’s important not only to consider sunlight exposure and shading but also factors like load-bearing capacity, drainage, and waterproofing. Proper design and execution of waterproofing measures during installation will prevent future issues, ensuring the longevity of both the solar system and the building it is mounted on.