What are the trending technologies in photovoltaics in recent years?

Diamond Wire Cutting Technology

The slicing process for crystalline silicon material represents a significant portion of non-silicon costs in the PV industry. Diamond wire cutting is a new slicing method that uses diamond-coated wire to slice silicon wafers at high speed. Compared to traditional slurry slicing, diamond wire is more cost-effective. Currently, monocrystalline silicon has fully adopted this technology, and the transition from slurry to diamond wire for multicrystalline silicon is accelerating.

PERC Cells (Passivated Emitter and Rear Cell Technology)

The key distinction of PERC cells is the passivation layer on the rear surface, which reduces electron recombination and improves light reflection. By the end of 2018, global PERC cell production capacity was around 70GW, with annual output exceeding 55GW. It is projected that by 2019, global PERC capacity would approach 100GW, maintaining its dominant position in high-efficiency solar products.

"Diamond Wire + Black Silicon" Technology

Black silicon technology improves the absorption of light and enhances cell efficiency by reducing surface reflectivity through additional texturing processes. Dry black silicon technology offers the highest efficiency gains but requires substantial capital investment. Wet black silicon, with lower costs, offers a 0.3%-0.5% efficiency boost and is gaining traction.

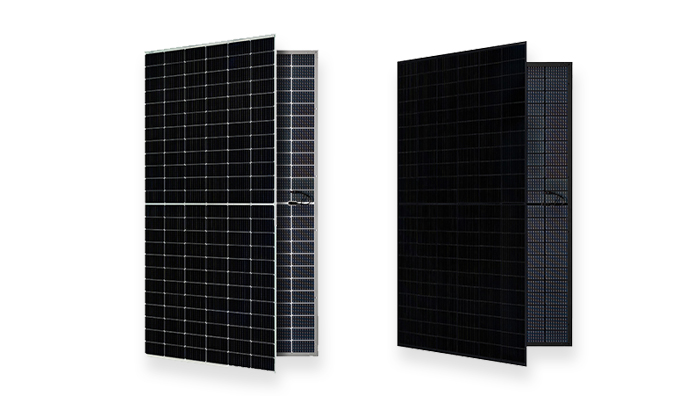

Bifacial Cell Technology

Bifacial cells represent a major breakthrough in recent years. These cells absorb light from both sides, boosting energy yield by 10%-25% depending on environmental conditions. The production of N-type monocrystalline bifacial cells has been expanding in recent years.

MBB (Multi-Busbar) Technology

This technology uses 12 busbars, improving current collection, reducing internal losses, and minimizing shading, which increases module power by at least 5W. It also reduces the chances of microcracks and improves performance even when minor damage occurs.

Shingled Cell Technology

Shingled cell modules use sliced cells arranged tightly together, allowing 13% more cells in the same area. This design eliminates the need for soldering ribbons, reducing resistance losses and significantly increasing output power.

Half-Cut Cell Technology

Half-cut cells reduce current losses and improve power output by approximately 10W compared to full-cell modules. Additionally, half-cut modules run cooler, with hotspot temperatures around 25°C lower than their full-cell counterparts.