The photovoltaic panel EL detector is a kind of instrument which is used to detect photovoltaic panel (solar panel) . It is based on the electroluminescence principle of crystalline silicon. Electroluminescence (el) is a phenomenon in which an applied voltage accelerates the movement of carriers in a List of semiconductor materials under the action of an electric field, converting part of the kinetic energy into radiant energy. The photovoltaic panel EL detector uses this principle to capture the near-infrared image of crystalline silicon by a high-resolution infrared camera and obtain the image of the cell.

The main function of the photovoltaic panel EL detector is to accurately detect various defects of the photovoltaic panel, the parameters include gate breaking, crack, fragment, fragment, braze welding, sintered mesh, black core, Letter boxing, blending, low efficiency chip, Edge etching, PID, attenuation, hot spot attenuation, etc. . These defects may affect the performance and quality of photovoltaic panels and, if not detected and addressed in a timely manner, may adversely affect the efficiency and stability of the entire solar power generation system.

In addition to being able to accurately detect the defects of PV panels, PV panel EL detector has other advantages. For example, it has high accuracy and efficiency, can quickly and accurately detect the location and type of defects. In addition, the EL detector has the Destructive testing advantage that it will not cause physical damage to the photovoltaic panel under test or affect its performance.

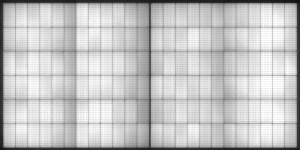

Qualified EL test images are as follows:

Here are some of the common flaws in photovoltaic panels:

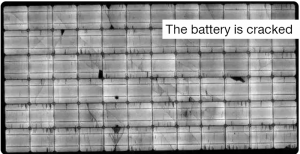

The battery is cracked

(1). Causes: the panel of the battery was cracked due to external force during welding or treatment; at low temperature, the panel of the battery did not undergo preheating treatment, and after a short period of high temperature, it suddenly appeared expansion, resulting in cracking; The temperature of the battery is too high at the moment of single welding or serial welding.

(2). Module effect: it causes the power attenuation of the module, and the hot spot effect will be caused when the module runs for a long time, which will directly affect the performance of the battery until the module is burned down and scrapped.

(3). Preventive measures: in the course of welding or processing to avoid the impact of external forces on the battery plate, in the course of single or tandem welding of the battery plate to pre-heat treatment, the working temperature of the electric iron must meet the technical requirements of the production process.

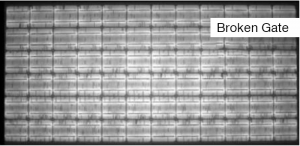

Broken Gate

(1). EL imaging features: from the El image, there are vertical lines between the two grid lines, and there are dark lines along the main grid line of the cell. At the same time, the weak light intensity or non-luminescence at the thin grating is mainly caused by the unconnected cells.

(2). Reasons: the main reason of gate damage is the breaking point of fine gate and the loss of fine gate, which lead to the main gate line and fine gate line can not form a loop. At the same time, the grid is not standardized welding or battery board printing, screen printing quality is not good or screen printing parameters are not set properly, cutting silicon uneven, fault.

(3). Module effect: while reducing the efficiency of photovoltaic module, it is not good for collecting current.

(4). Preventive measures: reasonable setting screen printing parameters, screen material collocation, establishing screen standard operating procedures, real-time monitoring RS can greatly reduce screen printing gate breakage, at the same time can be equipped with automatic sorting machine for on-line monitoring.

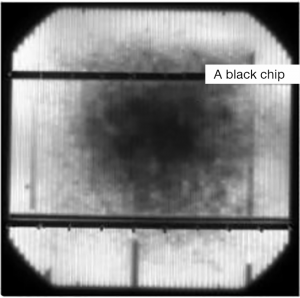

A black chip

(1). EL imaging features: in an EL image, you can see concentric circles that gradually brighten from the center to the edge of the cell. Part of the battery is black and the image appears weak or non-luminous. This forms a composite dense area, in the case of power, the center of the battery appears black area.

(2). In the process of silicon rod crystallization, the high segregation coefficient of silicon rod is directly related to the solubility of oxygen, and the silicon material is polluted to different degrees, cause part of the battery to turn black. At the same time, because of shortening the directional solidification time, the latent heat release and the temperature gradient matching of the melt are not high, the crystal growth speed is accelerated, and the main cause of internal dislocation defect is excessive thermal stress.

(3). Component impact: after the black chip appears in the component, the long-time running will cause the thermal breakdown, when the test component IV characteristic curve, the curve appears the ladder shape, the long-time running will cause the component output power to decline.

(4). Preventive measures: reasonably adjust the big coagulation coefficient and the solubility of oxygen in the silicon rod to avoid the pollution of silicon material.

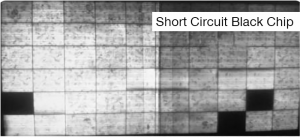

Short Circuit Black Chip (non-short circuit black chip)

(1). EL imaging characteristics: photovoltaic modules in a certain location will appear one or more pieces of all-black Battery.

(2). Causes: short circuit between positive and negative electrodes, reverse welding between positive and negative electrodes of junction box diode, faulty connection and virtual welding between the positive and negative electrodes, etc. , mixed low-efficiency cell units, and poor quality silicon wafers or N-type wafers are misused. The absence of PN junctions is also one of the reasons why EL imaging is completely black.

(3). Component effect: the filling coefficient and the output power of the component will be greatly affected. The output power of the whole PV module is reduced, and the maximum power of the IV characteristic curve is reduced.

(4). Precautions: when the battery is welded, solder is left on the edge to avoid solder joints at low temperatures. After the assembly is laminated, check whether the junction box diode is welded and whether the lead wire is abnormally welded.

In short, the photovoltaic panel EL detector is an important detection tool, in the solar power system plays an increasingly important role. It can not only improve the photoelectric conversion efficiency, reduce the cost, promote the development of renewable energy, but also ensure the stability and efficiency of solar power generation system.